Proactive measures are key to grain bin safety

Canadian Agricultural Safety Association (CASA) Farm SafetyWe all know that there are dangers associated with working around grain.

But all too often, we hear farmers downplay the risk of grain entrapment, claiming it won’t happen on their farm. And that’s a dangerous mindset to have, particularly considering it takes just seconds to be engulfed in grain.

“It’s important to get farmers to understand the severity and gravity of grain entrapments,” says Catherine Rylatt, co-founder of the Grain Handling Safety Coalition in the United States.

As Rylatt notes, farmers need to approach grain safety from a proactive rather than reactive perspective. Because once someone becomes trapped in grain, it’s too late.

“It’s very easy to say, ‘It’s rare, that won’t happen to me,’ ” she says. “And yet, grain entrapment is not as rare as many think, because when you talk to farmers, many know someone who has been trapped in grain.”

Here’s a look at how to stay on top of grain bin safety, including what to do before the harvest season starts and how to enter a grain bin safely.

Keeping grain in good condition

One of the most effective ways to stay safe around grain is by staying out of it altogether.

That means taking steps to maintain the grain’s quality. A common cause for why people become trapped in grain is when a bin’s product becomes spoiled. Making sure that bins are ready ahead of time for harvested grain can significantly reduce the risk of spoilage.

Start by inspecting the area around the grain to ensure there is no garbage or debris. Spilled grain attracts insects and rodents, so take care to clean up and properly dispose of any grain on the ground.

Before cleaning inside the bin, verify that you have the proper personal protective equipment (PPE), along with a safety harness and lifeline. Also, ensure the area is well- ventilated by opening the door and roof hatch. If the bin has motorized moving components, such as a bin sweep, it’s crucial to lock out the controls before entering the bin.

Since even small amounts of mouldy or insect-infested grain can contaminate a bin filled with a new harvest, it’s vital to thoroughly sweep and (if possible) vacuum all surfaces to remove all residual grain, dust, and other particles. Make sure that all harvesting equipment (combine, trucks, etc.) is thoroughly cleaned to remove old grain and prevent contamination.

This is also an ideal time to check that all electrical components are functioning correctly and make any necessary repairs. Don’t forget to check for any holes or rusted panels and bolts, as well as inspecting the seal at the bottom of the bin.

Once the harvest season is underway, it’s crucial to monitor the condition of your grain. Creating a schedule to check the temperature and moisture levels inside the grain bin can help prevent grain from spoiling due to mould and insect infestations.

“We really try to stress the prevention measures [of grain safety], which includes keeping grain in good condition and preparing bins for harvest,” explains Rylatt. “Because if you do those prevention things, you’re significantly less likely to have out-of-condition grain, and if you don’t have out-of-condition grain, there’s going to be little need to go in the bin.”

Safely entering a grain bin

While staying out of a bin is the best way to be safe around grain, there are instances when entering a bin is necessary, such as removing spoiled grain. But doing so means closely following safety procedures.

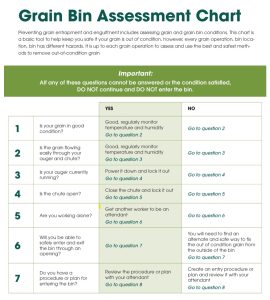

The first step for entering a grain storage structure is to complete a checklist that addresses critical safety issues and

When it comes to mitigating hazards when entering a grain bin, one of the most critical safety aspects is the lockout/tagout process. Staying safe during grain bin entry requires more than just hitting an “off” switch, which is why this safety procedure is essential. With grain bins, the lockout/tagout process protects workers from unintentional exposure to hazardous energy by preventing the use of equipment during interior inspection or maintenance.

The main steps of a lockout/tagout procedure include:

- Notification: Tell other workers about the intended equipment

- Equipment shutdown: Follow standard processes to turn off

- Isolate energy sources: Disconnect equipment from energy sources (i.e., breaker, valve, block).

- Release stored energy: Remove or release stored

- Lock and tag: Install locks and tags on energy. One lock and tag must be installed per person entering the grain bin.

- Test equipment: Double-check that energy sources are disconnected from the equipment by trying to start it.

- Return to service: Once everyone has safely exited the bin, let everyone know that the equipment will be restarted. Ensure no one is near the equipment before reconnecting the energy source.

- Remove locks and tags: Locks and tags can only be removed by the person who installed them.

When to call professionals

If your grain bin requires substantial remediation that’s beyond what you can handle or if you lack the proper means for a safe grain bin entry process, it’s best to contact professionals for assistance.

Companies that specialize in grain bin cleaning have the knowledge, training, and equipment necessary to safely and efficiently remove grain. What that means for your farm is the ability to keep everyone safe while getting operations back on track as quickly as possible.

Remember that farm safety should never be rushed. Being proactive about grain bin safety will go a long way towards protecting you, your workers, and your farm’s success.

Raising awareness about grain safety

The BeGrainSafe program is a grain safety initiative of the Canadian Agricultural Safety Association. In 2025, BeGrainSafe Week takes place August 11-17 and is presented by Corteva Agriscience. The program is also supported by G3, CN, Farm Credit Canada, Agriculture Financial Services Corporation, Alberta Canola Producers Commission, Alberta Grains, Canadian Canola Growers Association, Nutrien Ag Solutions, SaskOilseeds, Sask Wheat, Viterra, Grain Farmers of Ontario, Manitoba Canola Growers Association, and Prairie Oat Growers Association.

For more information about grain safety or BeGrainSafe, visit www.casa- acsa.ca/BeGrainSafe.

The proceeding article was provided by the Canadian Agricultural Safety Association (CASA) a national, non-profit organization dedicated to improving the health and safety of farmers, their families and agricultural workers. CASA is funded in part by the Sustainable Canadian Agricultural Partnership. For more information, visit www.casa-acsa.ca.